One of the important conditions for the construction of a high-quality and durable furnace is using the right brick. No material is suitable for this task. It must be borne in mind that the conditions in which the used brick will be located are special. This is an open fire, high temperature and its sharp drops. Therefore, the brick must have refractoriness, refractoriness and high quality. Meets these requirements. But it’s not at all necessary to put the whole furnace out of it, since it is quite expensive. It is possible to reduce the cost of constructing a furnace thanks to the use of a conventional chimney and, for cladding, a brick.

What some authors call the middle house was a very common type of housing in São Paulo, especially in areas close to the center. As in popular houses, this type of housing also had a well-defined kitchen space, albeit a smaller one. In fact, this type of dwelling was closer to the palaces, at least in terms of circulation. A kitchen was added at the end of the house. But, unlike the popular house, it was often added to the pantry and the room for the maid. Thus, the specialization of the service area was closer to the mansion.

What properties should have a brick used for laying a furnace

Another difference from small houses was that the kitchen was connected directly to the dining room, and not to the bedroom. The differences in the kitchens of the described houses make it difficult to determine how such kitchens will be organized during this period. In simpler dwellings, space instability prevailed, small, poorly lit and poorly equipped. Only in palaces all the requirements of posture and sanitary rules were observed. However, often a gas stove was located in the pantry and served only to warm dishes coming out of the kitchen into the dining room.

Of course, you can choose the right type of brick by brand. However, it is better to first deal with the technical characteristics of different product samples. For example, it is important to know that a good kiln brick differs from a conventional refractory brick in its ability to withstand temperatures in excess of 1000 degrees. In addition, brick for stoves must cope with temperature extremes. However, such products are also divided into various types based on several criteria. For example, by composition, bricks are divided into:

In this context, when the kitchen was the focus of health authorities, domestic equipment would play a decisive role in the necessary changes. Among this equipment, the stove, as we can see, stood out as a cooking center in the new kitchen. The Sveta Group has focused on promoting the domestic use of new fuels, choosing a gas stove as its main product. Thus, there is significant progress in domestic technologies available for consumption.

The technology offered by foreign companies promised this desired adaptation of the new kitchen to hygiene and at the same time tried to overcome the backlogs and old colonial habits that were considered undesirable. However, confrontation of the image with the text of the advertisement reveals the underlying resistance and poorly hidden burden, as well as the extreme and significant ambiguity in identifying message recipients.

- quartz. In their manufacture, sand and clay are used for firing;

- the main ones. Such material is used, first of all, for the construction of metallurgical furnaces; at home, its use is practically absent;

- carbon. For their manufacture, graphite is used. In everyday life is also not applied;

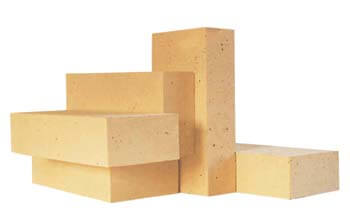

- fireclay. For furnace production the best option. They can be operated at temperatures up to 1600 degrees, while retaining their characteristics perfectly and are not destroyed. Of the shortcomings, one can distinguish a rather unsightly appearance (it has a yellowish tint). Therefore, mainly chamotte brick is used for laying fireboxes, and on top the stove is faced with another brick to give it a more aesthetic appearance.

In this case, the technology appears as an abstract and universal instance, imposing itself in any context, whether in the United States or in Brazil, where there is an obvious problem of inconsistency. Gas was to be sold to an ignorant and disinterested public; and since domestic consumption was considered vital to the development of energy companies, it was necessary to increase sales of household appliances, especially stoves.

In Brazil, the stove was mainly associated with firewood as fuel and was in the yard, outside the house, or pulled out. The gas company took advantage of this situation and anchored much of its propaganda in this idea of \u200b\u200bevolution and progress opposed to wood and gas. It is difficult to determine the diachronic typology of furnaces, since they succeeded and coexisted in a series of equipment with various forms and types of fuel. Even with all this diversity, the main competitor of gas, without a doubt, was the forest.

Basic requirements for kiln bricks

Since the operating conditions of the kiln brick are extreme, then increased requirements:

- it must withstand high temperatures and not collapse when exposed to open flame;

- high heat capacity of the brick and the preservation of heat for a long time are necessary;

- the material must be strong enough;

- a brick should not be afraid of sudden temperature changes.

All important technical conditions that any product must comply with are specified in GOSTs. As for the ceramic bricks from which the solid fuel furnace is made, they must comply with GOST 390-96. This document entered into force on July 1, 1997 and describes the shape of the product, size and operational requirements depending on the maximum temperature.

Due to its low price and the simplest type of equipment, it was the most commonly used fuel in the kitchen. There are several references to his presence in the mansion kitchen through newspaper ads and auction catalogs. Some properties have been described in terms of the amenities offered. According to Carlos Lemos, the main characteristic was its size and the possibility of using mineral or vegetable coal, which is very common among Italian immigrants. They differed from the previous ones because they were compact and made of iron with the same characteristics of gas furnaces in their general morphology, but with completely different fuel and operation.

Obviously, the bricks used for the manufacture of heating facilities must have characteristics that differ significantly from those of other building materials. This is primarily due to the fact that surfaces in furnaces are sometimes heated. up to 1000 degrees. So, they must be composed of bricks that begin to change their state at temperatures noticeably above the specified threshold.

What bricks can not be used

The production and sale of gas stoves was directly related to the initiative of the company, since it owned a monopoly on the production and distribution of fuel through pipes connected directly to houses. The first devices were imported directly by the company and supplied with the gas connection. In their advertisements, trying to seize the place occupied by firewood and coal, gas companies presented the idea of \u200b\u200bevolution, the top of which was gas, dropping firewood to complete obsolescence.

In addition to very strong heating, stove bricks have to experience significant temperature changes. Under various environmental conditions, the temperature can quickly drop even to negative. Such strong vibrations lead to the constant expansion and contraction of the material. Therefore, the brick must be very strong, so as not to collapse in such conditions.

The announcements, even when highlighting the successes made on the new stoves, sought to emphasize the importance of gas. There are several links to the organization and layout of kitchen equipment. In advertisements, the hob area is clearly seen as the center of space, surrounded by a sink and desk. Some home manuals describe kitchen furniture.

Kitchen furniture: a central table for washing dishes. Sinks are washed with hot and cold water in a clear place. A coffee table to wash next to the sink. A cloth hung on a hook to wash another pot dish. Shelf for dishes away from the stove. We have a cutting table next to the stove, a wood warehouse.

Also for stove bricks are very important high thermal conductivity and ability to retain heat for a long time . The first characteristic allows you to quickly transfer heat from burning fuel to the environment. Thanks to the second brick, even after complete combustion of the fuel, it remains warm for some time and continues to heat the room.

Thus, the recommendations made by experts represented the kitchen arranged around the stove. In order to clean and organize, the article defines the main kitchen furniture: a table next to two stoves and a sink with hot and cold water. Of course, in this case we are talking about an ideal kitchen, organized to optimize homework, but only the presence of water, gas and electricity in the houses became possible for such an organization. In any case, there was an obvious unprecedented concern about the space that was so discredited as the kitchen, which began to mobilize engineers, energy companies, educators, government agencies and, above all, doctors.

Parameters by which a brick is selected for external furnace work and masonry chimneys

There are a number of characteristics by which a brick is chosen for the laying of external furnace walls, as well as chimneys.

Brick density

Experts recommend first of all choosing a brick by density. She  determined by the brand consisting of the letter M and a number from 25 to 1000. The technical conditions of the brand for density are specified in GOST 530-2012. This parameter is absolutely not related to product quality, but only characterizes the density of the brick. It is important in terms of the rate of heating and cooling of the material. The higher the density (the greater the number in the brand), the more time it takes to heat and cool the brick.

determined by the brand consisting of the letter M and a number from 25 to 1000. The technical conditions of the brand for density are specified in GOST 530-2012. This parameter is absolutely not related to product quality, but only characterizes the density of the brick. It is important in terms of the rate of heating and cooling of the material. The higher the density (the greater the number in the brand), the more time it takes to heat and cool the brick.

Both the text and its images define a model example of the kitchen ideal pursued by public authorities with public approval, and, of course, energy companies that used this discourse to stimulate gas and electricity consumption. On, we see the maid's activity in a clean and organized kitchen. There are no signs of dirt during preparation of the raw materials. The center of cooking in the kitchen stands out in the photo: a table and a sink. But the text under the figure emphasizes the limits of a hygienic and organized kitchen model, "as circumstances permit."

The advantage of a stove made of dense material is that it holds heat for a long time after burning the fuel. But at the same time, it is rather difficult to heat such a furnace, especially at low ambient temperatures. Therefore, it is recommended to use material with moderate values \u200b\u200bfor oven masonry (grade in the range from M150 to M250).

Of course, reality imposed restrictions on the desired transformation. However, the text is clear when it comes to an ideal situation. The goal is clearly defined: We do not mean the modest cuisine of families who have excessively modest habits, but the modern cuisine, which should be “modeled”. The expression “families with overly modest habits” is an elegant euphemism for poverty. Of course, the article is directly related to the possibility of equipping the kitchen for richer classes. But we must once again emphasize that the demonstrated kitchen is a model that does not exist as such, but is an ideal.

Frost resistance

This parameter defines the number of heating and cooling cycles, after which the brick remains intact. Frost resistance is indicated by the letter F and a number from 15 to 100. This characteristic is especially important for bricks from which chimneys and pipes are laid. It is these structural elements that experience constant heating and cooling. Sometimes the swings are large, and the brick must withstand them. For cold regions, it is necessary to take a brick with frost resistance closer to F-75, and it is better to refuse cheap samples with an F-15 or F-25 index.

The text goes directly to the one who will be responsible for the purchase of the device and fuel, turning to rational and technical arguments. In the images, the connection of the furnace with the grid does not appear, but from reading the text we can conclude about the dependence on the company, whether it is maintenance or the availability of meters and pipes. Several advertisements show that the stove is working, and when they do, the job looks like an easy and enjoyable activity. In several images in which a woman appears using a plate, she is always located in the lateral direction to provide better visualization of the equipment.

Thermal conductivity

This indicator is closely related to brick density. For kiln masonry, a material with a thermal conductivity of 0.59-0.72 W / (m × ° C) is suitable.

Fullness

For masonry use extremely solid brick.

Characteristics of the brick used for laying the furnace

To lay out the inside of the furnace, take fireclay bricks, which happens these brands: SHAK, SHA, ShB, ShV, PB, PV and SHUS. Such a brick should be softened at a temperature of 1300 degrees and above. It should be uniform in structure, have a high density and low porosity.

But his position is elegant, offering a small mobilization and always with work in progress, without interference in management. His only concern seems to be monitoring the progress of the work. Also in the advertising discourse appears medical discourse, accepted even by engineers, architects and government agencies, linking the gas stove with hygiene. The person, as the recipient of this propaganda as a buyer, was stressed the need for healthy food. In addition to ensuring hygiene and cleanliness, the oven will be able to transfer these qualities into the food cooked in it.

Very high demands are made on fireclay bricks, since it determines how long the stove will last and how it will perform its functions. Therefore, the choice of brick for laying stoves should be approached as seriously as possible.

Now there is something to choose from, however, it is not easy to choose the most suitable material. Experts advise staying on refractory fireclay semi-acid brick. It has a reasonable price with good quality, while it has good thermal properties.

The man’s role will be exhausted when purchasing a gas stove and paying monthly for gas supplies, data that are not specifically presented in this advertisement. Final gains overshadowed the growing dependency to which it would be exposed in the house. We must remember that gas supply worked through a network of gas pipelines, which affected supply, maintenance, price, etc. Relations with a service provider have entered a new area. Mediation has become undifferentiated and professional. The company was the only possible mediation, without an old personal relationship of intimacy with potential suppliers who visited door-to-door.

The main properties of various brands of fireclay bricks are shown in the table:

| Characteristics | Normal grades | ||||||

| SHAK | SHA | SB | BW | SHUS | PB | PV | |

| Fire resistance, ° C | 1730 | 1600 | 1650 | 1630 | 1580 | 1657 | 1580 |

| Porosity,% not higher | 23 | 24 | 24 | 24 | 30 | 24 | 25 |

| Tensile strength, N / mm 2 | 23 | 20 | — | 20 | 12 | 20 | 13 |

| Softening start temperature, ° C | 1320 | 1300 | |||||

How to determine the quality of the brick?

Methods and methods for determining whether a brick meets the established requirements are indicated in GOSTs. Guided by them, you can check whether each parameter matches the normal value. So, GOST 5402.1-2000 allows you to set the residual deformation of the brick after heating. According to GOST 4069-69, the fire resistance of the brick is checked. And according to GOST 151136-78, it is possible to measure damage to the corners and edges of the products.

The old estates were replaced by business and capitalist relations, regulated by contracts, with rights and obligations established and protected. In its advertisements, the gas company did not in any way explain the addiction to which the house was exposed, but offered “free” several services that proved this addiction. In most gas company advertisements, the stove always appears as a direct source of income, regardless of whether it saves time or money or avoids troubles or dirt in the kitchen.

However, at home, it is not possible to carry out all verification procedures provided for by these GOSTs. They are unrealistic to perform without special devices that are available only in laboratories. Therefore, when choosing a brick, you can ask for certificates of conformity, and it is also advisable to turn to a good specialist for help.

But his obvious connection with the company was obscured by a speech. In advertising, we can determine the degree of this dependence on the services offered: The company will charge the stove for free and check, clean and store it for two years. If your home does not have a meter, pay a small deposit in addition to buying a stove.

This set of relations translated into reconfiguration of housing space, associated with private capitalist interests and regulated by state power. But, as in any system, one of the main factors was associated with adaptability. The input of electric energy and gas, with household appliances at the tip, brought changes and resistance, but also fixtures. The concepts of progress explored by energy companies and endorsed by the elites were hardly inserted into the Brazilian public order.

Furnace masters have sufficient experience to distinguish quality products from low-quality. It is important to know that for the construction of the furnace, brand material from M150 to M250 should be taken, and a certificate must necessarily indicate that this product is intended for furnace work.

However, in the absence of the necessary experience, you can use simple techniques to check the quality of the brick:

- A large face of the product must be struck lightly with a hammer. If the brick is of high quality, then the instrument will bounce off the surface with a loud sound.

- The brick must be inspected for compliance with the established shapes and sizes. The permissible deviation of actual dimensions from GOST standards is 2 mm.

- After sawing or splitting a brick, you need to inspect the internal structure. In a quality product, the color inside should be uniform. If there are spots, this indicates internal stresses, which in the future can lead to the destruction of the brick when heated. Also on the surface of the chip should not be chipping material.

Using such simple methods, you can choose a quality brick for construction work. It is very important to consider that only the use of materials that comply with current GOSTs will help to build a furnace, which will become a reliable and durable heating device.

The following photos show several types of brick products.

Manufacturers

Brick "Borovichi" (Borovichi, Nizhny Novgorod region)

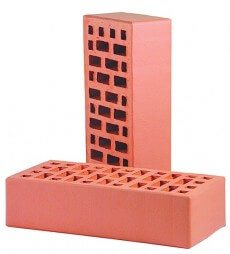

Red brick M250, has high frost resistance. Since 2011, it can be freely purchased in the construction markets. Has 3 working surfaces. The edges of the brick are rounded. The products are of high quality, while the price is quite affordable. This makes this material one of the leaders in the market.

Unfortunately, the manufacturer admits the presence of not very high-quality copies in its products. Some products vary significantly in size from standard ones (deviations sometimes reach 1 cm). Therefore, it is recommended to order this product with some margin so that you can select high-quality products that are enough for masonry. Here you can not do without the help of an experienced master. Otherwise, because of the non-standard sizes, you will have to make too thick seams and file bricks. And this will affect the appearance of the unit.

Brick "Vitebsk Workshop 1"

Red brick M200. Frost resistance is quite low. Therefore, do not put external walls from it, and also work with it in places with high humidity. Two working surfaces. The edges are sharp. There are no significant deviations in size.

Now such a product is very common in specialized retail outlets. It is good for laying furnace bodies, but you can’t make a furnace from it in any case. When in contact with an open flame, such a brick is only enough for a year. Therefore, the use of this material is possible only in conjunction with fireclay bricks. Exterior elements of the chimney should also not be put out of this product. It should be noted the very affordable price of Vitebsk brick.

Brick "Vitebsk Workshop 2"

Red brick M180 – M200. In terms of frost resistance it is at the level of previous products, and in appearance it is even worse. Therefore, such a brick is suitable for laying invisible furnace elements.

Brick "Fireclay (refractory)"

Such products are produced by many Russian factories. The quality is different for everyone: there are very good samples, but there are also extremely unsuccessful ones. At the same time, the price does not differ significantly. High-quality chamotte brick should have a high density, uniform cream color, sharp edges. The standard brick size is W8, but manufacturers offer different sizes and shapes.

The main purpose of fireclay bricks is the laying of fireboxes of stoves or internal elements of fireplaces. But you can not be limited to only the hottest parts of heating devices, from this material it is quite possible to build the whole furnace.

Oven "bread chambers" - special departments where you can bake bread - have now gained some popularity. Not too competent specialists use chamotte brick for their arrangement. This is strictly not recommended. Nevertheless, fireclay brick is a product of the chemical industry, the contact of which with food is extremely undesirable.

Brick "LODE"

Red solid brick M500. It is made in Latvia. It has high frost resistance. Therefore, it is great for outdoor work. Has 3 working surfaces. Edges and edges are made slightly rounded. The manufacturer offers various forms of bricks, for example, semicircular. The appearance of this product is very attractive, because it is widely used for facing work.

Stoves and fireplaces have become popular again in recent years. Rarely can you see a country house without a cozy and warm hearth. But, of course, when building a fireplace or stove, you don’t want to get into a mess and rebuild the entire structure due to the wrong material.

In this article we will try to find out which brick is best for laying a furnace.

What type of brick to choose

Let's try to understand its types, features and boundaries of application, as well as find out which brick - which brand is used for laying stoves.

Types of bricks

First of all, this product should be divided into subspecies based on the material from which it is made:

- ceramic: made from a mixture of various clays by firing;

- silicate: consists mainly of sand and lime, plus a small percentage of additives. The resulting mixture is made solid not in a kiln, but in an autoclave. By adding pigment, you can get the product of any desired color.

One clarification should be made: the explanatory dictionary says that a brick is a bar from a mixture of baked clay. That is, based on these words, silicate is not a brick at all.

The builders themselves, as well as the stove makers, draw a clear line between the two types of bricks. And even GOSTs on them are different. Accordingly, our main focus will be on ceramic bricks.

Types of clinkers, based on the application:

- - in fact, the building brick itself, from which all internal masonry is made;

- front - it is also finishing - they make parts of the finished structure visible to the eye. It is made more accurately, with a uniform color, with more clearly defined and even edges. It is often hollow to preserve heat.

Brick Specifications

We are well aware of what kind of brick is needed for the stove: of course, fireproof. After all, the temperature in the furnace can reach 1000 degrees Celsius.

In addition to resistance to fire, the material also has the following parameters:

- strength - i.e. the ability to resist stress and strain, while remaining solid;

- mark - this is the same letter M, which we used to see in various directories. For example, double silicate brick M 150. M 150 here means that this instance is able to withstand a load of 150 kg per cm3. On sale, markings from 100 to 175 are most often found, although 300 can be found;

- frost resistance - the ability of the product to withstand a certain number of freezing and thawing cycles;

- water absorption indicated as a percentage. Always consider what exactly you will build by looking at this indicator. Easily absorbing water is not suitable for building foundations, for example.

- weight and size - This indicator matters when calculating the future dimensions of the structure. Do not lose sight of him.

- thermal conductivity - Again, a very interesting indicator for us. A bad heat transfer will not be good in building a stove with your own hands.

Types of Refractory Bricks

- - it gives off heat well and tolerates temperature changes, is not subject to chemical reactions, including with alkalis. The price is quite reasonable and cannot but please. The only negative - a temperature above 1000 degrees destroys this product very quickly. One of the most suitable options for us. In the photo below you can see it.

- quartz - A slightly more expensive option, also subject to chemical reactions. It can be used only in isolated places, so as not to cause its destruction.

- periclase - made from a complex mineral composition, the name of the minerals will not say anything to a layman. It is widely used in industry, especially metallurgy, due to its resistance even to ultra-high temperatures.

- carbonaceous - It is made from pressed graphite and has an extremely highly specialized purpose. It is not used for stoves and fireplaces, therefore we will stop on this.

It is important to understand that there is no need to build the whole furnace entirely from refractory bricks. After all, it is more expensive and does not make any sense. The chimney, for example, can be folded out of ordinary, as well as a firewood man with an ash pan, because they do not have too high a temperature, ordinary red is quite capable of withstanding their temperature regime.

Advice! In addition to using refractory and ordinary bricks, do not forget about thermal insulation. It must be used in the construction of the outer walls of the stove or fireplace, so that there is no fire hazard situation.

Types of Thermal Insulation Bricks

- - its air chamber will easily maintain the required temperature of the furnace;

- cement sand - has negligible thermal conductivity, which will avoid fires and isolate the fireplace area from the whole house;

- foam diatomite - performs the same functions as the previous type, while it has a significant minus - it does not withstand temperatures above 900 degrees.

The most common brands and manufacturers of stove bricks

- fireclay bricks for furnaces from the Borovichi Combine and OJSC Novomoskovskogneupor

To summarize

You have read the instructions on which stove brick is better. You also learned that during the construction process various types of bricks can be combined, with the goal of not overpaying once again. Of the above companies, Vitebsk and brick of the Lode company are in greatest demand.

The video in this article will help you learn more about the disadvantages and advantages of bricks from these manufacturers.