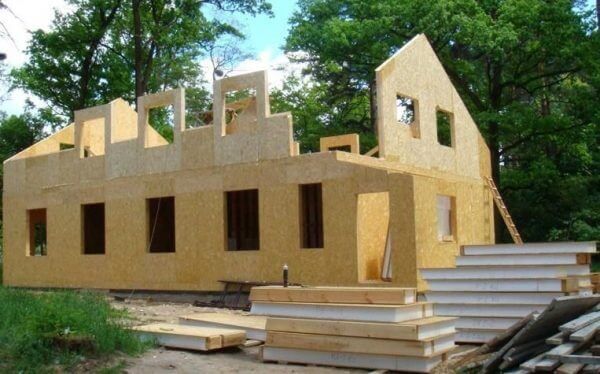

The construction of frame houses in Europe began in the century before last. The bottom line is simple - a frame is created from the beams, which is then closed up with diversified boards. Now “Finnish” houses have become very popular.

Finnish technology for building frame houses implies about the same, but ready-made blocks and wet building materials are used here. In this regard, you can build a frame house year-round. Usually, already processed boards are used, so often the decoration of the facade is not required. Finnish technology, in comparison with Canadian technology, is characterized by more advanced construction techniques.

Finnish frame houses in Russia began to “grow” back in the days of perestroika. This word means a panel structure made of wood, which is assembled by fastening finished panels.

Why us

We have our own production, talented design engineers and architects work for us, who will quickly calculate the amount of material for your project or help design a frame house from scratch. You just need to use our technology for the construction of Finnish prefabricated frame houses to assemble your own designer housing.

Advantages of ordering Finnish house kits in our company:

- high quality building materials and their proper storage in our warehouses;

- fast delivery of the home kit to the place of future construction of the house;

- professional advice on the construction of buildings from our materials.

Finnish frame houses are an excellent alternative to any other construction, since their construction takes a minimum of time.

Construction of Finnish frame houses

Frame houses using Finnish technology are very easy to assemble. So, let's say you already bought our home kit. What to do next?

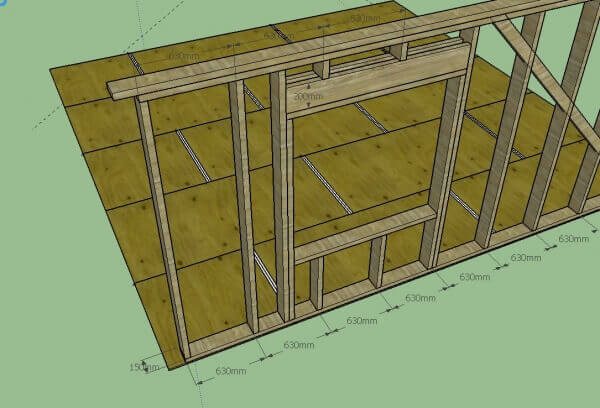

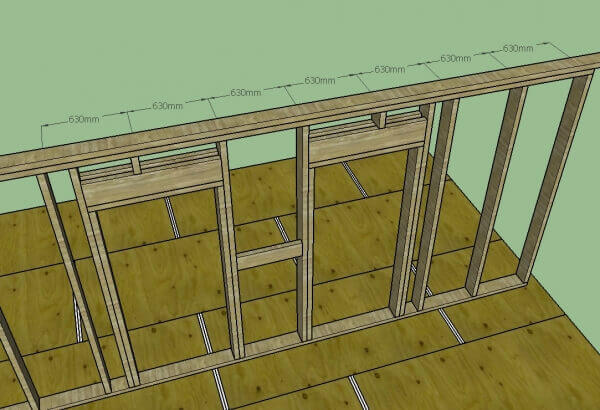

- At the construction site, put together all the wall partitions, install the floor. Just lift the wall panels and fasten them together. We will provide you with a home construction scheme.

- Make a solid strip foundation. This will be followed by the installation of a frame from a beam and the assembly of the lower floor, panels from OSB, a draft floor is laid.

- Proceed to fasten key nodes. They are interconnected using metal brackets.

- Next, mount the beams - erect an interfloor overlap, lift the wall panels of all floors, depending on the number of storeys of the building.

- After that, you will have very little left: mount the roof rafters, waterproofing and finish the house from the inside.

Finnish prefabricated frame houses are distinguished by the presence of elements manufactured by the factory. Assembling the frame and panels is a very simple job, which you will certainly cope with.

If after reading our material on Finnish frame houses you have questions, please contact us by phone listed on the website and get a free consultation.

In contact with

Classmates

Frame house - one of the most affordable and budget options for suburban construction.

But as soon as it is laid down, no less crucial stage begins: the device, which in such buildings has its own characteristics.

They must be studied before starting construction work in order to avoid major repairs of the entire structure in the near future.

![]()

For frame house frame wall structures have only two types:

- Bearingwhich have increased resistance to shock and mechanical stress: both vertical and horizontal. Usually they are made from a solid board or giant I-beams. Doorways in the bearing walls are assembled using at least 2 jumpers fastened with nails in 2 rows, which helps to avoid their deformation.

- Bearing (internal), which serve as partitions for dividing the building into rooms and are not designed to support the weight of the building. The jumpers above the doorways in such cases should have a width equal to the width of the vertical pillars and be made of material with a thickness of more than 40 mm.

Reference! Internal partitions intended for zoning of living space are often made of 40x100 timber, since they do not need a thick layer of insulation. For load-bearing walls, materials with a cross section of at least 50x150, and preferably 50x250, are taken in order to be able to increase the thickness of the insulating layer.

Materials

What material is used to assemble the walls of frame houses? If you have chosen frame houses for your housing: wall material can be completely different.

It is determined not only by aesthetic properties, but also by the ability to withstand certain loads, climatic and relief features of the site, weight and other characteristics.

For the device of wooden frame walls and partitions mainly use:

- Wooden beammade from coniferous wood or maple. Its cross section has a square shape, and the standard size is 150x150. A thicker beam (150x200 and 200x200) is ideal for multi-story buildings or houses with an attic.

- Edged board from coniferous wood. The cross-section of the racks is usually 50x150.

- Wooden tee, which is two timber timber, fastened with a jumper from the OSB-plate. It allows you to freely adjust the shelves depending on the thickness of the insulation and the size of the foundation. According to experts, the use of such a material minimizes the risk of frame deformation during shrinkage of the structure and provides better thermal insulation.

- Materials for external and internal casing of the frame. These include both standard wooden boards and prefabricated panel-type constructions made of OSB-plates, hydrophobic plywood or boards. And the use of magnesite sheets is also allowed. At the same time, it is important that the materials are well-dried and that there are no cracks and defects in them, which in the future can cause shrinkage and destruction of the house. As antifungal protection, they are necessarily treated with special antiseptic compounds.

- . They are soft - insulation based on fiberglass, basalt wool - and hard - polystyrene foam and its extruded modification - type.

- Decoration Materials. These include vinyl and metal siding. The latter is characterized by increased strength, easy to install and has increased resistance to corrosion. Vinyl siding attracts less weight and a large selection of colors, but is afraid of temperature extremes and direct sunlight. And also a block house is often used (calibrated boards with an oval transverse profile and a castle connection, which look completely reminiscent of a round log) and imitation of timber (panels with a rectangular section and beveled corners). Frame houses decorated with artificial stone, acrylic coatings and decorative plaster look very elegant.

- designed to protect the house from blowing and moisture. It looks like a rolled material that resembles a film, but at the same time it is vapor permeable to prevent the insulation from freezing in the wall in the winter season. Mostly for this purpose they buy a diffusion membrane for waterproofing.

- Vapor barrier, which is used as a vapor barrier membrane.

Reference! According to one of the innovative technologies, the supporting frame of the structure is completely made of galvanized thermo-profile, and shotcrete concrete or foam concrete serves as the internal insulation. This makes it easy to build a strong and reliable house with the number of floors from 1 to 5.

Technology

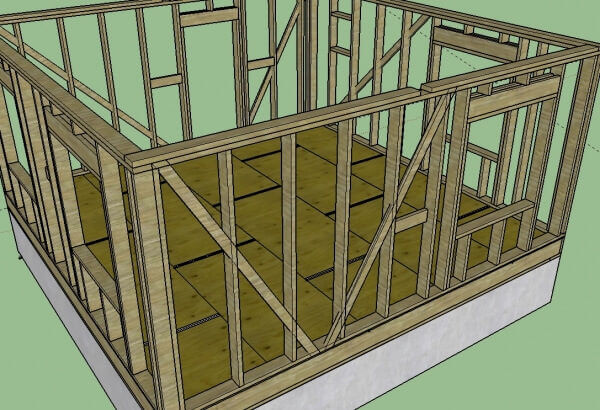

A frame house can be built in various ways, since today several effective technologies for creating its walls are known. The most popular among them are: the wall structure of the frame house according to Finnish technology and Canadian. Their differences are that, in accordance with the Scandinavian method, wall panels are assembled directly at the construction site, but construction technologies from Canada involve the installation of a frame from ready-made SIP panels (frame-panel technology).

Finnish

Finnish is as follows:

- They mount the frame from the beam, after which it is assembled.

- They assemble panels, for which they use OSB-plates, with which spans of walls are sheathed both from the inside and from the street.

- Install a heat-insulating layer, after which a rough floor is laid on the floor.

- The main components of the building are interconnected by metal brackets and the beams of floors are installed.

- On the interfloor overlap, the panels of the walls of the second floor are assembled and installed vertically.

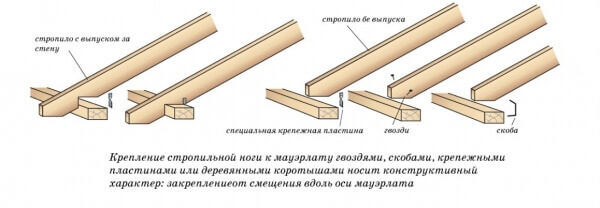

- Mount the roof rafters, fix the waterproofing layer on them and lay the roof.

- Produce interior and exterior finishing work.

Canadian

When designing a building according to Canadian technology, the work algorithm is as follows:

- The strip foundation is poured onto which the panels and floor beams are mounted.

- Bars are placed in the gaps, which are interconnected, and the slots are insulated with mounting foam.

- After installing the ceiling, walls are installed, starting from the corners. In two-story houses, the installation of interfloor ceilings and walls of the second floor is carried out. At the same time, the panels are attached to the bars with self-tapping screws every 10-15 cm. All joints are reliably sealed with mounting foam. Fastening is done according to the principle of a thorn groove, and the thermal gap between the wall panels is 3-5 mm. At the same time, window and door openings are being made.

- The final step is the installation of the roof.

Device

What does the wall of a frame house consist of?

No matter how sophisticated the design of your frame house, and what expensive materials were not used, the design of the frame wall with insulation, especially the carrier, will be almost identical.

It is multi-layered and is called “sandwich” or “pie” in building jargon.

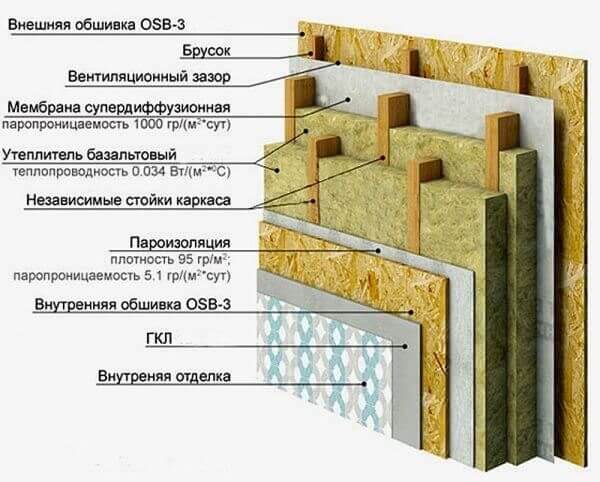

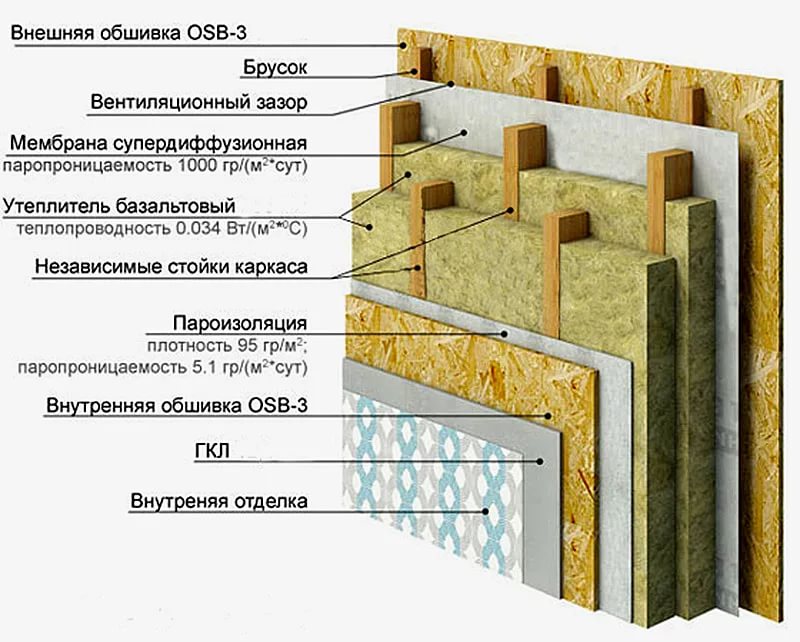

So, the frame wall: the design consists of layers:

- Directly carcass.

- The inner finishing layer.

- Vapor barrier.

- Insulation.

- Waterproof layer.

- OSB boards.

- Exterior decorative finishes.

Important! It is much simpler to make the internal partitions of the structure: the frame wall diagram contains only the frame posts, a heat-insulating layer, a vapor-insulating membrane installed on both sides, and drywall or OSB-plate.

The correct pie of the frame wall can be very different and depends on the wishes and financial capabilities of the owner, as well as on the external conditions and internal loads to which the building will be subjected. Consider the structure of the walls of a frame house in detail. The most common options are:

- Skeleton wall cake with mineral wool. The correct cake of the wall of the frame house with mineral wool is ideal for buildings in which there should be good sound insulation. To do this, the frame of the wall from the outside is sheathed with chipboards and lined with waterproofing film on the outside. On top of it, mineral wool is attached, which can be supplemented with extruded polystyrene foam. A vapor barrier membrane layer is installed on top of the thermal insulation layer (from the inside): it is fixed with a stapler. Then the crate is mounted for better retention of the heat-insulating layer and the final decoration of the wall is carried out. It is important that moisture does not penetrate deep into the wall, as this will lead to the loss of mineral wool, which has increased hygroscopicity, of its insulation properties.

- Pie of the wall of a frame house with ecocotton wool. It is considered the safest for human health, because ecowool is completely safe and provides air permeability inside the wall, preventing the formation of condensation. This insulation is lightweight and excellent heat-shielding properties. The “pie” itself consists of the following layers: the inner finishing layer, vapor barrier film, carcass elements, ecowool (it is evenly blown over the entire surface of the wall, which avoids joints, as in the case of other heaters, and the penetration of cold into the house), a windproof membrane and external finishing layer, which is separated from the previous ventilation gap.

- Pie of the wall of a frame house with basalt insulation. This is an expensive solution, however, basalt wool not only has good heat and sound insulation properties, but also is resistant to vibration, mold and fungus. The composition of the frame wall in this case will be standard: interior finish, vapor barrier, frame structure, basalt filler, windproof membrane and exterior finish.

- Frame wall cake with OSB (or OSB). Such plates are used to give walls greater rigidity and stability. The classic layout of the layers, which provides optimal moisture removal and “breathing” properties, looks like this: interior finish, vapor barrier, insulation (mineral wool or other), frame racks, OSB-plate, windproof layer, ventilation gap, exterior finish.

- Pie with Isoplat panels. Recently, they are very popular among builders, as they reliably protect the wall from moisture, are additional protection against the cold and completely replace wind and water protection. In the frame house, the layers of the walls are as follows: interior decoration, vapor barrier film, heat insulation layer, frame racks, Isoplat panels, lathing, exterior decoration.

- "Pie" on the EIFS system. Structural elements of the structure framework often become a kind of "bridges" of cold, which requires additional - the formation of polystyrene foam cocoon from their outer side. The composition of the wall of the frame house in this case will be as follows: interior decoration, vapor barrier, frame layer with a mesh, rigid PSB-S 25F polystyrene plates, wind protection and a layer of exterior decoration.

Important! In the above options, "pie" a windproof layer means a layer consisting of waterproofing and wind protection. Since there must be a layer of waterproofing on the outside of the wall, which protects the insulation from external moisture.

Drawings, diagrams and sections

If you are going to build a frame structure yourself, without a detailed drawing, on which the frame wall in section will be indicated, can not do.

This will allow you to clearly imagine the location and installation procedure of all supporting structures and internal partitions and to avoid the most common mistakes.

Important! The drawings clearly indicate not only the options for connecting structural elements to each other, but also the layout of the engineering communications.

Largely modern drawings of the walls of the frame house are made in specialized computer programswhere such parameters as the type and, the location of load-bearing walls and partitions, the number of rooms, external parameters such as humidity, type of soil, average temperature in a given area, etc. are entered.

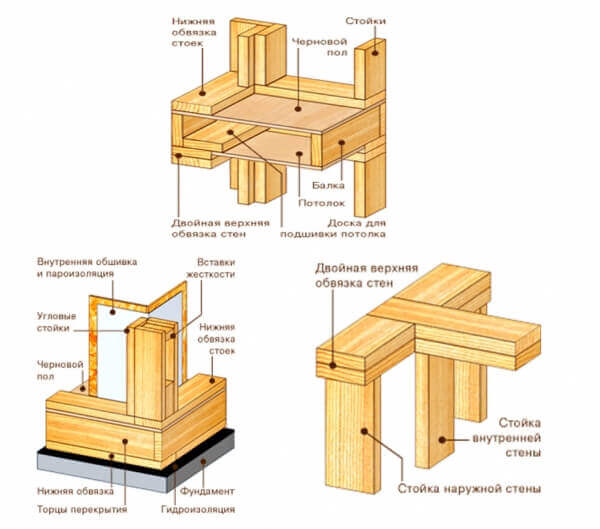

The diagram and structure of the wall of the frame house necessarily contains the following:

- Type of wall and its dimensions.

- The nuances of the structural connection of the walls with each other, as well as with the floor and roof.

- Location of window and doorways.

- The sequence of layers (thermal insulation, vapor barrier, etc.), their thickness, installation features and type of materials for each of them.

Knots

What is a wall unit of a frame house?

The wall of the frame structure consists of the following nodes, the nuances of which you should know:

1. The adjacency of the wall to the floor in the frame house. Wall frame racks must be nailed with 3 nails of 90 mm in size, and this is done through the rack in the lag. This applies to supporting structures. If the wall is located on the lag harness or jumper, then the third nail is hammered in them. In the case of partitions, one 90 mm nail hammered into each lag is sufficient.

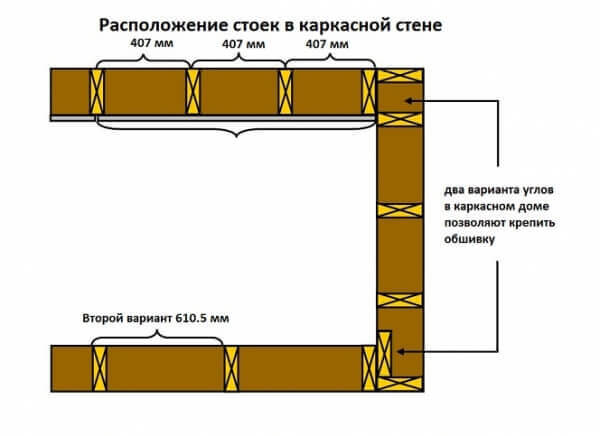

2. The connection of the walls of the frame house.To ensure a reliable connection of the frame walls - to connect the side and front walls of the building, in the side frame you need to make an additional rack, deployed perpendicular to the corner rack of the frame structure located on the edge. This will allow you to correctly form the inner corner and simplify the process of finishing with plywood or OSB boards.

3. The angle of the frame wall. Just connecting the bars with a section of 150x150 (or boards with a section of 50x150) in the corner is fraught with its freezing in the winter. Therefore, the angle is made according to the 2 + 1 scheme. To one of the extreme racks of the frame structure they beat a third, which is deployed at 90 degrees. You can also strengthen the design by supplementing it with a fourth board.

Two racks are connected parallel to each other or at a small angle by means of 5 90 mm nails with a distance of 6 cm between them. Before finishing the corner, it is necessary to put a heater.

4. Ukosina.This is one of the most important elements of the wall, which gives it spatial rigidity and avoids distortions in the structure. They cut into both the lower and upper piping strictly at an angle that does not go beyond 45-60 degrees. They must be used if the paneling of the house with plywood or OSB-plates is not planned. It can be wooden with a section of 25x100, 50x150 or metal.

5. Window and doorways.

Important! In Canadian and Finnish technology, they are enhanced a bit differently, so these nuances should be taken into account.

In Canadian technology, double racks are used to create them. Under and above the opening, shortened racks are mounted, the distance between which remains the same as between the main racks. A header is placed above the opening made of doubled or tripled boards 10–25 cm high, depending on the width of the opening and beam load. Under the opening, horizontal boards are also mounted, cutting an additional rack in half: they will withstand the weight of the window.

In the case of doorways or the use of Finnish technology, a crossbar is installed instead of the hider - a board placed on the edge, which cuts in front of the lower trim in the upper part of the frame racks both inside and outside. The crossbar can be both single, and built. For it, boards with a size of 50x200 mm are taken.

6. The connection of the wall and the roof. Racks are mounted strictly perpendicular to the wall, but can be parallel in partitions or on the pediment of the roof. Beams should be monolithic, and at least 2 posts should be placed in the outer corners of the wall frame.

7. The connection of the wall and floor. Shown above in the figure to paragraph 1.

A photo

Sectional wall of a frame house: photos are presented below.

Useful video

How to make a frame wall cake is additionally described in the video below:

findings

The construction of the wall of a frame house is a rather important and painstaking process, but even a lay builder can cope with it without a problem and desire to learn and take into account any nuances.

In contact with

By structure, the walls of houses built using this technology include quite a lot of layers of different materials.

The first step in the construction when applying the Finnish technology for the construction of wooden houses is, of course, the installation of the frame, which is carried out according to a pre-developed plan or project.

The frame structure is mounted from boards. Outside, the finished frame structure is closed with plywood with antiseptic and antiseptic coating, or OSB boards.

Next, a film (membrane) is pulled onto the frame structure - it prevents vaporization. This material prevents the passage of water into a wooden house, and protects against blowing. Also, the membrane can pass through itself the vapor emanating from the interior to the surrounding atmosphere.

For the frame, the most technological will be the use of a thermal profile.

After, in accordance with the Finnish technology for the construction of houses, the frame is covered with film - there is a decoration with material for further decoration of the house. At the same time, you can choose any finishing materials - good, on the market they are presented in a wide range.

So, usually for buildings folded according to Finnish technology, the decoration is made of brick, siding, or special plastering is used. It is worth noting that as the main material for finishing a wooden house inside, you can use glass-magnesium sheets - sml.

Naturally, the frame inside the wooden house is empty - and so, it must be filled with insulation. In this case, basalt cotton wool or polystyrene foam is used. Or it could be mineral wool.

Next, the frame structure is pulled with a film that serves as a vapor barrier. Then, drywall is nailed to the frame from the inside - and plaster is applied to it. ![]()

As materials for insulation, you can use both ecowool and foam glass.

So, if we turn to foreign experience, then the Finnish technology for building houses is used to build houses up to 5 floors high. In the Russian Federation, based on fire safety, the construction of houses with a relatively large number of storeys is prohibited.

Therefore, wooden houses, cottages and also buildings built in Russia using Finnish technology have a maximum of 2 floors in height.

The main pros and cons of Finnish houses

Step-by-step construction of a Finnish house.

The Finnish house is a one-story building, which has a symmetrical gable roof. Currently, the Finnish house is a fairly widespread type of cottage.

Instruction manual

1 The Finnish house is most often built from glued beams. This building material is made from selected wood. A quality beam will for a long time preserve all the properties of a solid tree. It is highly resistant to moisture and biological damage.

It is worth noting its remarkable thermal insulation properties. Walls made of such a material will retain heat well even in severe frosts. In the summer, the house will be cool.

2 Almost all materials for the construction of a Finnish wooden house can be purchased on the construction market. At the moment, they are all manufactured using proven technologies.

The necessary sets of parts are produced in the factory. Glued laminated parts have a special profile both in connecting cups and on surfaces.

3 When assembling parts, it is best to use a synthetic sealant. As a result, the beam can be laid perfectly evenly. The wall will be practically windproof. This design allows you to reduce the chance of rain moisture getting inside.

It should be noted that fitting parts during the assembly of the log house is not required. The construction of glued beams practically does not lend itself to natural shrinkage. The walls of such a house are not exposed to cracking and deformation.

4 As a foundation for construction, it is best to use a concrete slab, which has a minimum level difference. You can build a house on a ready foundation in about 3-4 weeks. Materials for building a Finnish house are relatively inexpensive.

To create a house design, it is best to contact the architects. They will be able to make a special project. Reliable and warm, the Finnish house will delight its residents for several decades, in addition, it looks very beautiful.

Finnish double tongue technology

We bring to your attention a unique Finnish technology - “Double sheet pile”. The uniqueness lies in the fact that the “Double Groove” has absorbed only the best of the two most common technologies for building houses in Russia from wood. This is an original Russian erection of a house from a bar, with its understandability, environmental friendliness, and Canadian frame house building with its unique thermotechnical and non-shrinking properties.

These properties are achieved thanks to the so-called two-row stacking of the tongue-and-groove dry planed board into the cut, the thickness of the board is 43mm and its width is 130mm. This design is very strong, since all joints are made with high precision at the factory.

The board enters the board very tightly in the castle joint and in the longitudinal profile (spike in the groove) and does not require heating and interventional seals. Thus, a general spatial rigidity is formed and we get a rigid hollow structure with rather thick and massive wooden side walls, which no longer require finishing, do not crack, the minimum shrinkage is 0.5-1%.

Now it remains to lay the effective insulation in the inner cavity of the wall, but with the condition that the film should not be used. Such a heater, in addition to low thermal conductivity, must have a vapor transmission capacity and which is not afraid of humidity. Only in this case will we get a warm and breathing wall. Unfortunately, a small range of heaters can satisfy all these requirements, one of them is Ecowool insulation.

Ecowool, this is cellulose impregnated with borax, it is an absolutely harmless insulation akin to wood, but in turn it is not combustible, it does not have a subsidence effect, in which different animals do not start because it is a good antiseptic. It is this material that we use in our walls. With the help of a blowing machine, its high-quality blowing into the walls is carried out, which guarantees non-shrinking islands. Fig 5, Fig 6.

It is also possible to use a plate heater that manually fits into the walls. This is Shetrok insulation. Shetrok is a synthetic insulation like sintepon, its properties are more modest, but it also does not support combustion, does not dust, does not emit harmful substances, is not afraid of moisture, does not sag, it also provides heat and a high degree of environmental friendliness to the wall of our house.

And of course, it is important to say that this house is being built quickly enough if we are talking about the house under the "Key", as a rule it is no more than 2 months. The cost is also less, in comparison with other high-quality technologies, which will allow you to compare the cost of the finished, finished according to all the rules of the house, as this is where the price catch is hidden.

Of course I would like to say about the minus of this technology. This is the specificity of projects where basically the principle of wall over wall is to be observed. Long walls over 3,5m, need to be bandaged with a cut. All this of course affects the appearance, you must admit it is specific, and it is economically unreasonable to finish it differently, unlike frame houses, which can be finished as you like.

To summarize the advantages of this technology:

1. Warm house according to SNiP, with a wall 188mm wide.

2. Breathable wall without any chemistry (binders), which gives the house the highest degree of environmental friendliness.

3. The house is being built immediately with decoration and no need to wait for shrinkage.

4. High-quality knots of connections as they are made at factory.

5. High-quality insulation, as it is applied mechanically.

6. The construction period of a finished house is less than any other technology.

7. Ease of installation minimizes the human error factor

8. High quality finishing material, since the board does not crack, does not twist, unlike profiled timber.

9. The absence during construction of heavy special vehicles. equipment that gives construction in any conditions, preserving the environment.

10. The cost of building a finished residential building for permanent residence under SNiP is lower than any other technology.

The construction of frame houses is an inexpensive and high-quality analogue to the construction of logs or stone. What type of frame house to choose and why it is so remarkable to build a frame house using Finnish technology.

Features of construction using Finnish technology

Why do many who decide to build a house choose Finnish frame houses? Frame houses using Finnish technology are simple - a house frame can be assembled in a couple of weeks, and the actual construction of a house can be completed in a couple of months.

In addition, Finnish-type frame houses are built from 245x100 mm timber or 150 × 50 mm boards, which make up the frame, and mineral slabs that retain heat in the house. It is because of the material of the frame and the simplicity of the construction of the frame house that such construction was developed. In addition, experts and builders note the following positive features that make Finnish technology so popular.

Construction of Finnish frame houses

Frame house on Finnish technology on a pile foundation

- Lightweight construction does not require "extra" hands for mounting boards;

- The construction of a house is possible at any time of the year;

- All the equipment used is quite affordable, there is no need to call special equipment for the installation of house parts;

- Frame-type houses built according to Finnish technology have high thermal insulation;

- Short terms for the construction of houses;

- Low cost of materials and all construction;

- High environmental cleanliness of materials - wooden frame and mineral insulation;

- High life of the house itself, even the internal insulation has a shelf life of up to 25 years, unlike Canadian houses;

- Superior quality of the base material - or board;

- Simplicity and ease of decoration of the Finnish frame house.

Stages of building a frame house

Installation of the foundation under the frame house

Strip foundation for frame house according to Finnish technology

In this regard, the Finnish technology for the construction of frame houses involves the construction of a fairly light construction, there is no need to make a massive and expensive foundation. A strip or column foundation is perfect.

On a note

You can save on a strip foundation by choosing slag concrete and concrete, on a column foundation using a solid red brick or erecting a concrete foundation. The depth of the foundation and the frequency of placement of the supports depends on the number of storeys and the future load on it.

Installation of bed and log

On the perimeter of the installed foundation, lodges are mounted, which are attached to the foundation with special anchors. Before fixing the lodge, you need to check all the sizes and correspondence of the diagonals. Further on the end is a strapping board to which lags from boards placed on the edge are attached.

Installation of lags for Finnish houses takes place with a step of 300-350 mm. The construction of Finnish frame houses is characterized by the absence of polystyrene as a heater, so treated ecowool can be used for the floor.

Assembly of frame walls

The walls of the future Scandinavian frame house can be of two types - hand-assembled on the ground and installed entirely at the construction site, or ready-made high-tech panels with built-in communications.

Finnish technology frame wall cake

What does the right Finnish frame house pie include:

- vapor barrier membrane;

- inner lathing - rails are installed transversely, so that between them there is a space for laying future communications;

- finishing work, the most commonly used drywall.

How Finnish frame houses are built - examples of work in the photo.

Frame house for Scandinavian construction technology

Covering the frame of the house

The finished wall frame is sheathed with windproof Isoplat sheets. These sheets will not only protect the walls from external influences, but also give strength to the structure. After that, through the ventilated gap of the crate, sheets of DSP (cement-bonded chipboard) are mounted.

Installation of the ceiling and roof in a Finnish house

If the construction is multi-story, ceiling of the first floor is mounted on the walls of the first floor of the frame with beams with a cross section of 245x50 mm. If, after the first floor, there is an attic or roof, 150x50mm boards and OSB sheets under the draft ceiling are selected for the rafters. Usually the roof of Finnish houses is mounted simple, gable, also with a small step of rafters.

Attic floor in a frame house using Finnish technology

Finishing work in skeleton houses according to Scandinavian technology, as well as the choice of cover for the roof is carried out in accordance with individual wishes and by the availability of funds.

Installation of ventilation systems

Particular attention in the construction should be given to the creation of ventilation in the frame house. This issue is relevant for construction with the use of high-tech finished walls, with already installed windows and communication systems.

Ventilation system in a frame house

Many builders neglect the installation of ventilation systems, recommending simply opening the window in the ventilation mode. But in this case, not only additional funds are spent on heating or cooling the house, but the insulation spoils along with the materials that are the main ones during construction.

If a seasonal house is being built - a summer cottage and there are not many rooms in the room, you can independently install the hood in a frame house. Installation of natural ventilation with supply valves will be without difficulties and will not bring additional costs. During the construction of a year-round house, the supply ventilation in the house should be installed at least in bathrooms and in the kitchen.

Tools for creating ventilation in a frame house

- spanners;

- hammer drill and / or drill;

- screwdriver;

- hammer;

- marker;

- clamp;

- ratchet wrench.

On a note

If during construction the question arose of how to make a hood in a frame house at the lowest cost, you can mount natural ventilation, for which you do not need any electrical equipment, which does not entail additional costs.

Natural ventilation in the frame house

- It is best to carry out installation before finishing the premises, right during construction. If the valve will be located behind the heating radiator, it must be temporarily removed and marked with a marker the location of future ventilation.

- A hole is made for the ventilation duct.

- In the formed channel, a ventilation pipe with a heater is mounted.

- The valve body must not touch the pipe, so it can be attached using a mounting foam. The body, like the pipe, can be insulated, or put on a noise absorber.

- A protective grille is worn on the outside of the ventilation pipe, and a special cover on the inside.

If, choosing a project for the future home, you chose Finnish skeleton houses, the construction will be solid and reliable, with the right choice of materials will save a significant part of the budget.

High-quality technology of Finnish economy class house-building has long been practiced in most countries of the world. Thanks to the competent ratio of price, quality and durability, many private houses are built using this technology. It should be noted that the low price does not affect the quality of the house, regardless of the number of floors.

What are Finnish timber frame houses?

Finnish frame house

Beauty. The building material of the house is wood, known to everyone due to its natural attractiveness and energy. It is known that people living in wooden houses almost do not suffer from phobias and depression. In addition, the tree has a truly unique property - to convey even the most insignificant design and architectural details and nuances at an understandable level.

Safety - Finnish houses pay no attention to temperature, wind, or moisture. No wonder these houses are being built in Germany, Austria, Switzerland and, of course, in Finland.

High environmental friendliness - in the process of building frame houses natural building materials are used. For example, for the insulation of ceilings and walls, foam, glass or mineral wool is used. Through the pores of wood, the house itself breathes, it is pleasant, cozy and comfortable for people who have breathing problems. Dust does not accumulate in wooden frame houses, and the electromagnetic radiation of household appliances is reduced to zero.

Simplicity - the construction of economical frame houses provides a simple system. For construction, you do not need to rent cunning lifting equipment, because the frame structure is small. A part of the houses is produced in the company "Scandinavian houses", which is located in Karelia. They are cheap and come to the customer ready. As a result, approximately 2-3 months after the start of construction, it will already be possible to populate the first tenants in new buildings

Saving. As you know, wood has the useful property of retaining heat. This can be seen if you count the tangible reduction in resources that are commonly used for space heating.

Any characteristics of the operation depend on two components - preparation for construction and the construction process. And the key to this beauty and long service life is a clearly crafted construction plan, which is just what frame economical houses have.