Today, sand is one of the most common building materials. This is the main element of construction. Its purchase must be approached thoughtfully.

The specific gravity of sand or specific gravity is the weight that fits in a unit volume. In most cases, a volume of 1 meter cubic is used for sand. In tables and directories, the specific gravity is indicated in grams per 1 cm³, kg per m ³ or in tons per m ³.

The specific gravity of bulk material can range from 1,500 to 2,800 kg per meter per cubic meter.

How much does a sand cube weigh? Him specific gravity Depends on the following factors:

- grain composition;

- size of fractions;

- mineralogical composition;

- size of solid particles - impurities;

- degree of compaction;

- humidity.

Density

Sand is bulk material. Its density depends on the size of the air spaces located between the solid particles. There are several types of density:

Sand is bulk material. Its density depends on the size of the air spaces located between the solid particles. There are several types of density:

- real

- technological;

- bulk, defined as the ratio of the mass of sand to the volume that it occupies. This value includes all voids and pores;

- conditional or true density is the limit of the ratio of the mass of sand to the occupied volume without taking into account the air cavities in it.

True density is always higher than real, and is a conditional, theoretical value. In practice, the material has a density close to bulk.

Sand fineness modulus

This indicator characterizes the grain composition of the material. By sieving it through special sieves, the content of certain sizes of gravel fractions in the material is determined. Depending on the size modulus, it is divided into:

- coarse-grained, with grain sizes of more than 2.5 mm. It can be a career or river type of material;

- medium-grained, with fractions from 2 to 2.5 mm;

- fine-grained, with grains from 1.5 to 2 mm.

Grain size affects flow building material and its water demand.

By size it is divided into 2 groups:

- Grade I, this group may include material with grain sizes from 1.5 mm;

- Class II, sand of any size.

Degrees of compaction and humidity

The specific weight of the material is affected by the way it is laid. There are 3 degrees of compaction:

The specific weight of the material is affected by the way it is laid. There are 3 degrees of compaction:

- state of natural occurrence;

- artificially compacted and rammed;

- poured.

Wet sand has a large specific gravity. Humidity affects even the volume, but not so much. The material stored on the street in the winter has up to 15% by weight of snow and ice.

Varieties of sand

Sand is natural and artificial. Natural species are classified according to place of origin.

- River. It is obtained from the bottom of rivers and is distinguished by cleanliness. It is yellow or gray. The grain size is from 0.3 to 0.5 mm. It is used in the preparation of solutions and mixtures, the device of drains. It is the most common species.

- Career. It is extracted by an open method. May be brown or yellow. It has impurities in the form of dust particles and small stones. Grain sizes can be from 0.6 to 3.2 mm. It is used in the construction of trenches and as a sprinkling under foundations and paving slabs. In washed and sifted form, it can be used for plastering and decorating, preparation of cement screeds.

- Nautical. It is extracted from the bottom of the sea and is of high quality. It is possible to use in all areas, but is used little because of the high cost.

Artificial material is made from hard and dense rocks by crushing them. The result is a material with a uniform composition, not containing impurities, but having acute-angled grain shape. Suitable for the preparation of high-strength concrete. The most common types are:

Artificial material is made from hard and dense rocks by crushing them. The result is a material with a uniform composition, not containing impurities, but having acute-angled grain shape. Suitable for the preparation of high-strength concrete. The most common types are:

- Quartzobtained by grinding and dispersing white quartz. It is used to create decoration, decorative and welding materials.

- Expanded clay, obtained by crushing expanded clay gravel and crushed stone or by roasting small residual clay rocks. This sand is considered clay. It is used in the preparation of lightweight concrete, for filling in pits, leveling surfaces.

- Slag. Crushing of slag into small grains is carried out by the method of its sharp cooling with water. Such material has grains of various sizes, from 0.6 to 10 mm. It is used when mixing concrete mixes.

Sand classification

- monomineral consists of grains of one mineral (quartz, micaceous, feldspar, hornblende);

- polymineral It contains several different minerals (quartz-micaceous, quartz-feldspar, micaceous-quartz, etc.).

To find out how much does a cube of sand weigh, you need to use the formula:

To find out how much does a cube of sand weigh, you need to use the formula:

where m is the specific gravity of sand, in kg,

V - volume, in meters in a cube,

p - bulk density, in kg per meter per cubic meter.

For 1 m³, the weight is equal to the density of the material. How much bulk density is, the seller should know. Humidity averages 6-7%. In the case of wet material, its mass increases to 20%. This difference must be added to the weight gained.

How much does a sand cube weigh?

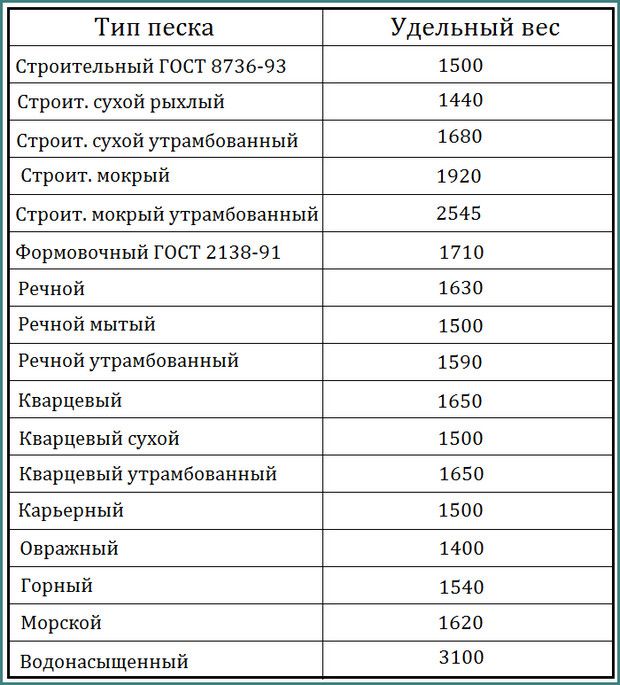

Different types of material have the following approximate specific gravity:

- river - 1500 kg per m3;

- marine - 1600 kg per m3;

- quarry - 1500 kg per m3;

- slag - 700−1200 kg per m3;

- quartz - 1400−1900 kg per m3;

- expanded clay - 400-1000 kg per m3.

For sand with different parameters, you can take the following bulk density (kg per m3):

For sand with different parameters, you can take the following bulk density (kg per m3):

- for river dry - 1400−1650;

- river wet - 1770−1860;

- compacted river - 1600;

- fine-grained career - 1700−1800;

- dry quartz - 1500;

- ground quartz - 1450;

- quartz compacted -1600−1700;

- expanded clay brand 500-1000 - 500-1000;

- made of blast furnace, waste and granular slag - 600−2200;

- molding normal humidity in accordance with GOST - 1700;

- dusty (with an admixture of dust) - 1600−1750;

- mining - 1500−1600;

- building, normal humidity according to GOST - 1550−1700.

When purchasing material, you need to correctly calculate the right amount. To find out how much you need, you need:

- multiply the required amount by a factor of 1.1–1.3, since during transportation and storage its volume changes;

- find out bulk density at the place of purchase;

- calculate specific gravity.

Do not rush into the purchase. It is advantageous to do this in the warm season and dry weather.

Sand is material that is considered No. 1 at a construction site, without it, it is difficult to carry out the construction of various kinds of structures. By itself, it is a loose mixture, which appears in connection with the destruction of rocks by water.

There are a sufficient number of varieties of sand that differ in their characteristics and have different applications. It should be understood that before the start of the construction process, you need to understand how much sand is in a ton.

Varieties

There are enough varieties of sand. Each of them has found its application in everyday life and construction. Below are the most common types of sand.

Outwardly, it is a bulk material, not ore.

You can find it at the bottom of the river, it is from there that they mine it. It differs from others in that it is the cleanest of all other types of sand.

Its advantage is that it does not: clay, dust, salt, pebbles and so on.

This type of sand is mined in two ways - equator draglines and hydromechanized method. River sand can be easily distinguished from others by its external data. It can be white, yellow, or with a gray tint. Sand is used in everyday life and construction.

If we talk about construction, then it used in the manufacture of reinforced concrete structuresas well as in the manufacture of paving slabs, road slabs and so on. Characteristics: density - 1.5 kg / m3, sand moisture - 4%, specific gravity - 2.65 g / cm3;

Sand is a special bulk material, which consists of small granules with a diameter of 0.05-3 mm.

It is formed as a result of the destruction of rocks that contain quartz in quarries. In its composition, it can have various kinds of impurities (clay materials, iron oxide, slag, and so on).

It is impurities that betray the sand of a certain shade, if we talk about pure quartz sand, then it is milky white. Him used in many areas: sandblasting, for the manufacture of glass, for the manufacture of concrete and other materials.

Due to its good characteristics, such sand can be painted in any color, which helps to create decorative plaster. Characteristics: humidity less than 10%, clay content 1%;

At its core, sand is an ore, bulk material, granular. It has particles ranging in size from 0.7-5 mm. There are 3 main ways to get this type of sand: sieving, washing, open method.

Sand in its composition has many impurities: dust, clay, small pebbles and so on.

This type of sand used in all foundation works and road construction works. Sand characteristics: particle size modulus 0.7-5 mm, impurity content 10%;

It is a non-metallic bulk material. Find it easily on the seabed.

Its advantage is that there are almost no impurities in its composition, but there is salt during cleaning. It is he who is considered the most popular today.

It has a wide range of applications, starting from a banal construction, ending with the production of various dry mixes. But unfortunately, this type of sand quite rare, since it is not always possible and convenient to mine it;

Since the above types of sand are natural (except quartz), artificial sand can also be noted.

It can be created by grinding marble, limestone, granite. In fact, it has a homogeneous composition, without impurities, and this allows the correct calculation of its consumption.

Before choosing the right sand, you need to know all its characteristics, and correctly calculate the volume of sand using the rules and formulas. The main characteristics of sand include:

- size, size indicator;

- radioactivity;

- specific gravity;

- direct indicator of bulk volume;

- the amount of impurities in the sand;

- coefficient ;

- coefficient ;

- density.

Properties of sand, its forms and types

Sand itself is not homogeneous, as it consists of different grains, and on this basis it can be divided into:

- coarse-grained sand, in its composition has grains with a diameter of 0.5-5mm;

- medium grained bulk material, consists of grains 0.05-0.25mm;

- the smallest type of sand, fine-grained - 0.25-0.05mm.

Sand is not only different in color, the shape of its grains can also be different: rounded, angular, sharp and so on. The shape depends on the transfer of material by wind or water.

Speaking of its composition, it is also divided into several main types:

- sand which consists of one mineral. For example, quartz sand or carbonate. In literature, you can find the name - oligomictic;

- sand, which consists of different minerals. It can be quartz sand with impurities. In technical dictionaries you can find the name - polymictic.

Why know the density of sand, why is it needed

Almost all building materials are both artificial and natural. Speaking of the latter option, it consists of grains with a size of 0.16-5 mm, and its bulk density is in the range 1300-1500kn / m3.

Most often, sand of natural origin is used in construction and everyday life.

Whatever type of sand you choose, you need to know that it has one very good property - to absorb moisture, removing it from other finished products, while increasing its flowability. It is logical that if the volume changes, the bulk density itself also changes, which in turn depends on how the humidity changes.

If, for example, humidity fluctuates in the range of 3-10%, then this material differs from dry material in its density. It should be understood that a grain of sand, which is covered with a layer of water, increases in volume, and this leads to an increase in the density of sand.

This suggests that when calculating construction work, it is worth considering (bulk density) and know how the density changes with increasing humidity. It is the quality level of sand that depends on its density index.

The density of different types of sand, such as, or will be slightly different from each other.

This is a very necessary characteristic, especially when it comes to professional construction, as this property affects the strength of the object, respectively, its life.

The density of sand is of two types:

- True

For a given amount affect Some factors to consider:

- the amount of impurity in the material itself (clay, dust, garbage);

- direct humidity level. Sufficiently wet factor, it is he who has an effect on density. If the humidity increases to 10%, then the density of the sand decreases, since different lumps form in it. But in such a situation, the volume increases;

- particle size sand. Since sand consists of small grains, to take into account its density, you need to know the fraction of the material;

- you need to take into account the type of sand, which depends on where the sand is mined.

For more information on determining the density of sand, see the video:

Specific gravity that affects it

- this is such a value that shows how much weight the material is dealing with in relation to its volume.

The calculation is carried out by a simple formula: specific gravity \u003d mass / volume.

This value is affected by two main characteristics that you need to know and consider:

- density. Since sand is a loose material, it is logical that it can loosen, or vice versa, compact from different influences. For example, during unloading and loading, sand loosens, its density decreases, mass per cubic meter also decreases;

- when the car is driving, the material is compacted (as the body is shaking). Weight per cubic meter increases, but with all this, the volume will be slightly less. For example, it can be noted that river sand is less compacted than quarry sand;

- moisture absorption and retention. Sand itself is a material that easily absorbs moisture and holds it, and this affects the increase in mass per cubic meter.

It is advisable to know how to calculate the volume of sand in m3, so that during the purchase of the material not to make a mistake in its weight. There is a specific procedure that helps to make the correct allocation. In order to carry out this process, you need to know the following sand parameters:

- the density of the material (you can take it in the table of the directory, since this value is already known);

- humidity;

- immediate level of compaction.

To show the whole situation clearly, you can take a fine-grained type. The density of such a material is 1700 kg / m3. The moisture content of the material is 6% -7%. This means that such material will have a weight of 1.8 tons with a volume of 1 cubic meter.

Laying tiles on the warm floor is no different from the standard procedure and does not require a special approach. all about the different types and properties of tile adhesive for underfloor heating.

Currently, among the population decorative plaster has become quite fashionable and widespread. By going through, get acquainted with the technology of its application.

Wall panels for the bathroom are strong enough, they are easy to install, they cope well with the temperature difference, they are durable, they are easily dismantled and removed. about the features of their selection and installation.

Many are interested in the question of how much sand is in the kamaz, since transportation will be carried out by just such machines. On the same example. The size of the body (average) is 12 cubic meters, we calculate the necessary weight:

1700 kg * 12 m3 \u003d 20.4 tons. If the sand is wet, and this figure reaches 20%, then the weight of the material increases as much as 4 tons. This shows that one dump truck can accommodate approximately 25 tons of sand.

If the construction is not very large, then sand can be taken in bags. It is convenient from the point of view of transportation and storage. The volume of sand in a bag of 50 kg is 0.038. This information is needed in order to make a solution in the correct proportion, because during the construction the concepts are used - m3, not kg.

Is it possible to accurately calculate sand

Of course, the exact amount of sand per ton is difficult to calculate, since for this it is necessary to know the above prescribed characteristics. But in order to know these figures, it is necessary to conduct laboratory studies, for this it is necessary to have exact numbers, and not those that we see in the tables (rounded).

Parameters such as humidity and compaction vary with the weather. This is what affects the accurate calculation of the volume of sand, but only to do this is extremely difficult.

To facilitate the task, the builders decided to take approximate figures for the calculation:

- humidity - 7%;

- density - 1600 kg / m3.

Of course, there will be a small error in the calculation, but it is more cost-effective than the decision to conduct laboratory tests. The volume of sand is calculated approximately. But in order to get clearer data, it is worth taking 1-3 meters more cubic meters.

This is necessary to take into account the losses that occur during transportation - it is compacted, dispersed.

findings

Sand has a wide range of uses.. The main one is the construction of various facilities. But this is not the only option where such material can be used. Sand is used in the agricultural industry, in housing.

In addition, in recent years, sand has found its application in the decoration of the landscape. Also, bulk material is used during the production of flooring and in the welding industry.

It doesn’t matter what type of sand you have chosen to work with, it’s worth correctly calculating the volume of sand in 1 ton in order to buy the right amount of material and correctly calculating the estimate.

Today sand is an important and necessary material, without which it is difficult to imagine a construction site of any scale. When buying sand, pay attention to all its characteristics and data.